Laser direct joining of metals and polymers using modulated cw laser radiation – one beam source for two processes

Authors: Dipl.-Ing. Andreas Schkutow, René Geiger, Prof. Dr.-Ing. Thomas Frick, M. Sc. Wolfgang Burgmayr

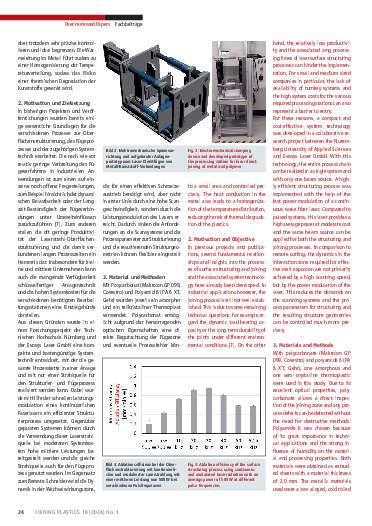

Laser direct joining of metals with polymers is based on two main processes: The surface structuring of the metallic joining part and the melting of the thermoplastic joining partner at the interface. Up to now, usually two different beam sources are applied for this purpose. Short pulsed laser radiation is typically applied for surface structuring and continuous wave laser radiation for the transmission joining or heat conduction joining process. In a research project conducted by University of Technology Nuremberg in collaboration with Evosys Laser GmbH, a new approach was developed in which both sub-processes are carried out using a single continuous wave (cw) laser beam source. A very efficient structuring process was realized by using the fast power modulation capabilities of the laser.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription