Investigation of the Welded Joint in Twin-Sheet Thermoforming

Authors: M. Sc. Lars Schmohl, B. Sc. Matthias Scholpp, M. Sc. Dominik Müller, Prof. Dr.-Ing. Christian Bonten

DOI: https://doi.org/10.53192/JP202502104

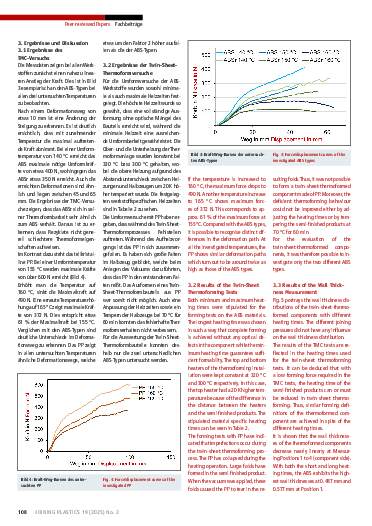

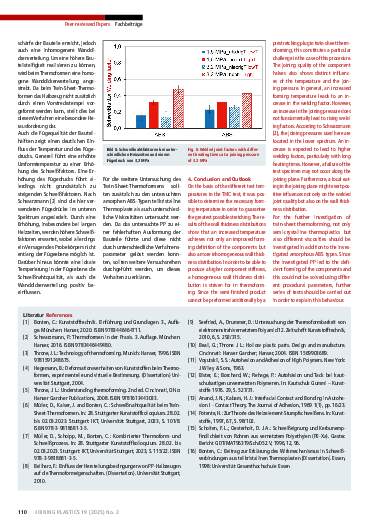

Twin-sheet thermoforming is a procedure in which tank-like or double-walled components can be manufactured from two-dimensional thermoplastic semi-finished products in a single fabrication sequence. In this respect, the thermoforming process is combined with a welding process in a single procedure. Since thermoforming is carried out in the thermoelastic

state and welding in the thermoplastic state, the welding process takes place in an untypical temperature range in the case of this procedure. The welded joint quality is therefore primarily influenced not only by

the temperature of the semi-finished product and its material properties but also by the applied pressure. In addition to these parameters, the geometry of the welding plane also has an influence on the welded joint quality. These interactions have not yet been clarified completely.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription