Hot Gas Series Welding of Components Made from Different Materials Using the Example of Polyamide 6

Authors: B. Sc. Meike Bornemann, Dipl.-Ing. Mirko Albrecht, Prof. Dr.-Ing. Volker Schöppner, Prof. Dr.-Ing. Andreas Seefried

DOI: https://doi.org/10.53192/JP202500296

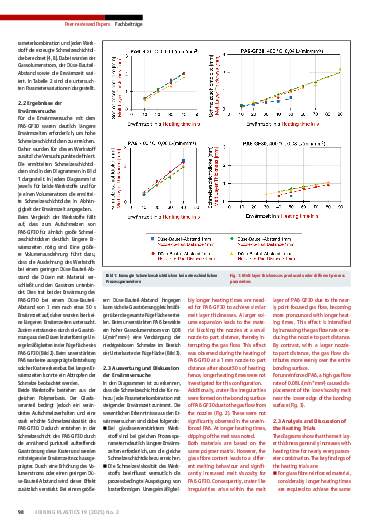

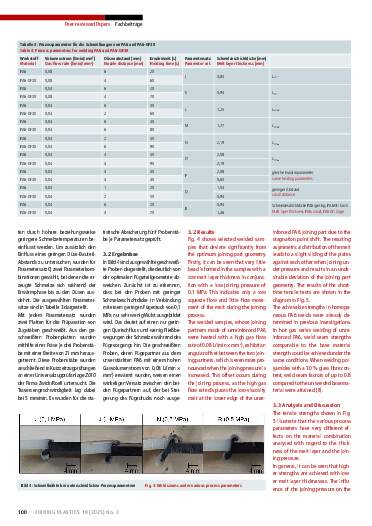

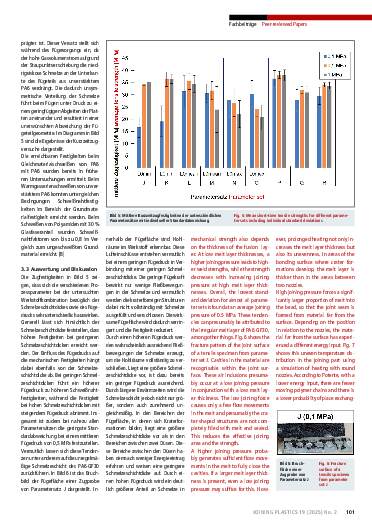

Hot gas series welding is a welding process for plastics that is gaining increasing industrial acceptance due to its numerous advantages compared to other established methods. Benefits include non-contact heating and relatively low-cost tooling compared to infrared welding. When joining different materials (e.g. PA6 and PA6- GF30), achieving high-strength welds usually requires material-specific adjustment of process parameters. The effects of varied process parameters (including heating time, gas flow rate, nozzle-to-part distance, and joining pressure) on the mechanical strength of welded joints between two different materials were investigated as part of the DLR IGF project 01IF22562 N. This paper presents the results of these investigations for the combination of unreinforced and glass fibre-reinforced Polyamide 6. It is shown how high bond strengths between two materials with different heating behaviours can be achieved. It was found that using identical heating parameters, which result in different melt layer thicknesses depending on the material, leads to higher strengths. Additionally, it was observed that by adjusting the joining pressure, process-induced irregularities in the melt layer can be compensated.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription